Accelerometers, Sensors and Cables

Condition Monitoring Analytics is a certified distributor for Connection Technology Center, INC (CTC). CTC is a leader in the industry of Accelerometers, Sensors and Cables so, we look forward to bringing the best there is to offer especially relevant to their comprehensive warranties and high quality service!

Products

- Accelerometers (Industrial Accelerometers, High Temperature, Hazardous Area Products and Low Power Sensors.

- Piezo Velocity Sensors

- Cables and Connectors

- 4-20 MA Products

- Also, Mounting Hardware, Junction Boxes and Accessories

Contact us for a quote or any questions you might have!

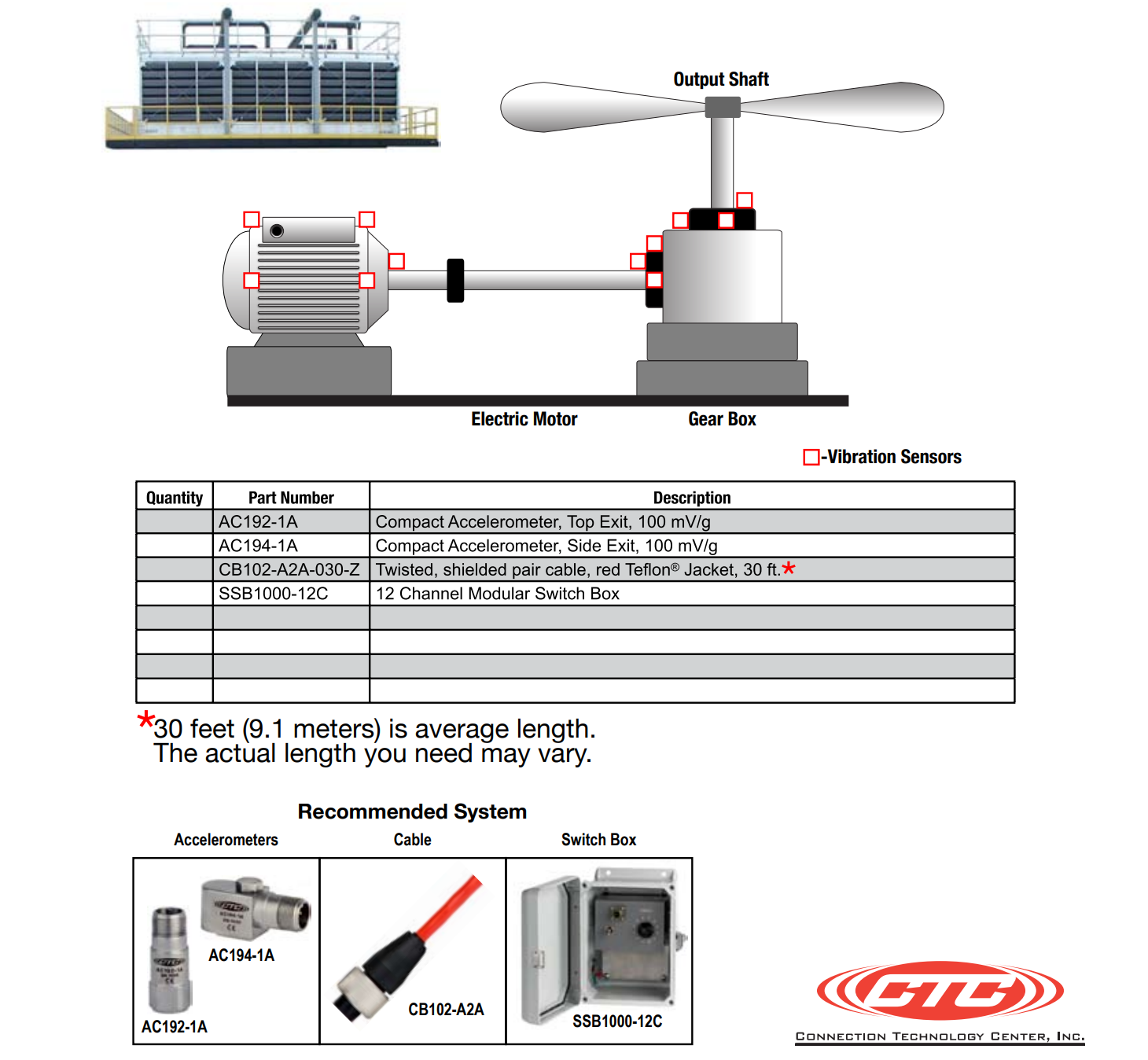

Cooling Tower Packages!

Most noteworthy, we’ve selected just what you need for your cooling tower applications. Accelerometers, Cables and Switch Box. Ask for a quote today!

Industrial Internet of Things (IIoT)

The Industrial Internet of Things (IIoT) is on fast pace to shaping the future of how we connect business, processes and deliver Big Data. Industrial Internet of Things requires and relies on sensors, devices and machines that contribute to physical business processes in the industrial setting.

CTC is providing products actively used in implementation of the Industrial Internet of Things (IIoT). In fact, CTC provided over 30,000 sensors and cables to one of the largest fleet-wide machinery monitoring projects in the United States, if not the world (Duke Energy’s SmartGen project). Furthermore, the SmartGen system gathers more than 605GB of data every week. Their goal is to eventually have smart, connected plant assets allowing self-diagnosis and service, autonomous asset operation, self-coordination of operation with other assets and systems.

Finally, Predictive analytics will use data, statistical algorithms and machine learning techniques to identify the likelihood of future outcomes based on historical data. Hence, Machine Learning will use real-time sensor data and learn from it continuously yet allowing for more accurate risk mitigation and prevention policies to intervene and avert catastrophic events via Advanced Pattern Recognition (APR).

Did You Know?

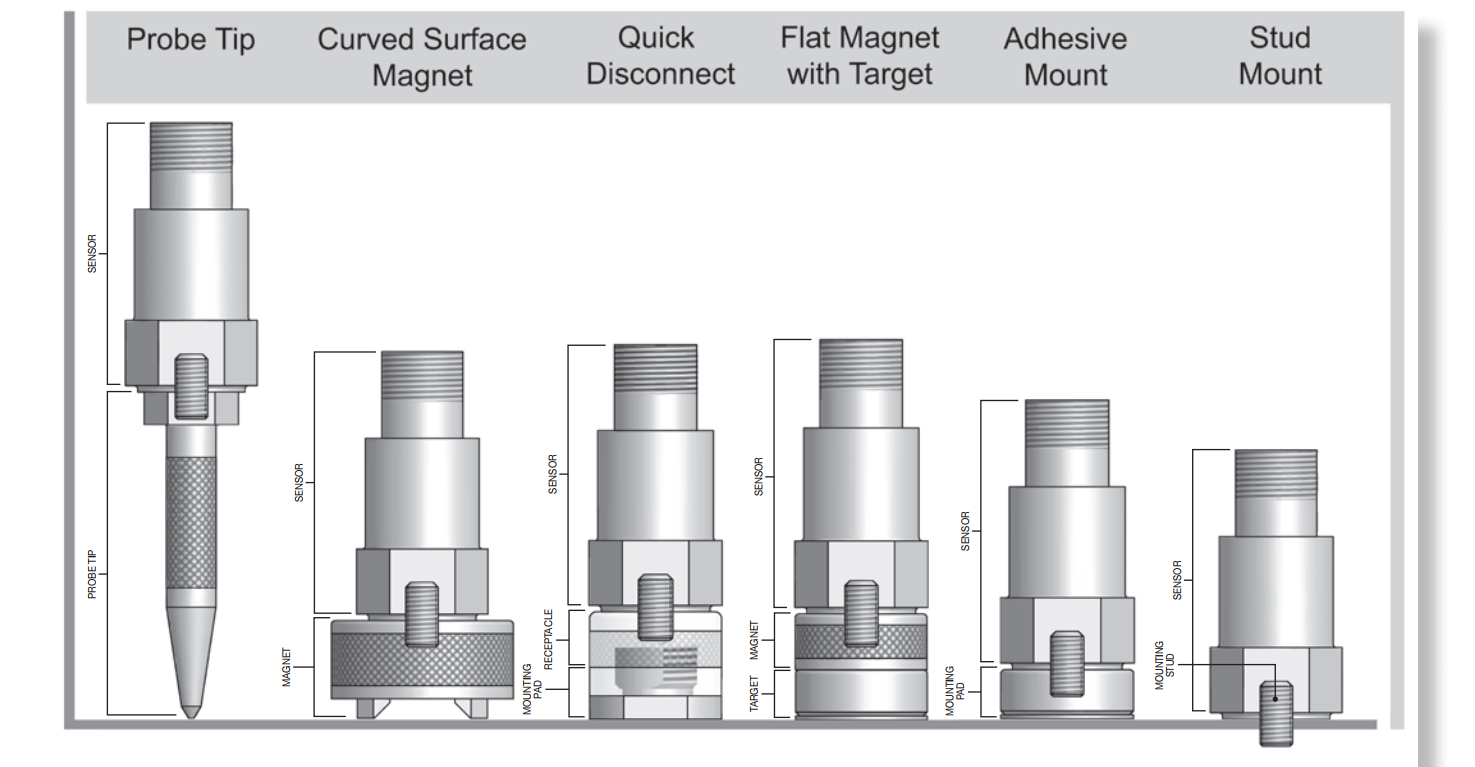

Frequency Response and Mounting Techniques

Accuracy of your high frequency response is directly affected by the mounting technique that you select for your sensor. Additionally, the better mounted surface area contact between the sensor and the machine surface, the more accurate your high frequency response will be. High frequency response is based on the sensor specified in addition to the method of attachment.

Finally, sensors that are stud mounted (epoxy mounted) are more often to utilize the entire high frequency measurement capability of a sensor. Therefore, this technique will maximize the surface contact of the sensor to the machine. Conversely, a probe tip mounted sensor has very little surface area contact with the machine surface, and offers very little high frequency accuracy above 500 Hz (30,000 CPM)

General guidelines are provided below for mounting techniques and corresponding high frequency response expectations.

Need installation services?

Condition Monitoring Analytics can put the right CTC products in your hands. Consequently, we also provide installation services when needed.

Warranty Return Instructions:

To return a CTC product for free calibration, repair, or replacement. Click here to fill out an Online RMA.

Finally, Condition Monitoring Analytics would like to serve your Accelerometers, Sensors and Cables needs. Contact us today for a quote!